Mar 27,2024

Tips for using explosion-proof impact wrenches to disassemble corroded nuts

1) Remove the nuts with less severe corrosion. First, use a tapping wrench to tap around the nut, and then drop some oil on the bolt and nut. After a period of time, use a tapping wrench to turn the nut clockwise, forcing the rust on it to fall off, and then turn the nut counterclockwise. Repeat two or three times, usually to remove the rust on the nut. 2) Remove the severely corroded nut. The method is basically the same as 1), except that there is no oil dripping on the bolts and nuts, but a "soaking" method is used. The soaking time is several hours, during which the nut is occasionally tapped with a tap wrench. 3) If the above methods are ineffective or urgent to disassemble, local heating can be applied to bolts and nuts using heat sources such as acetylene welding or spray lamps, forcing the oxide skin at the corroded area to peel off. The coefficient of thermal expansion of nuts is larger than that of bolts. When the nut is heated to a dark red color, use an impact wrench to unscrew it while it is hot, so that the severely corroded nut can be unscrewed for a longer period of time.

Mar 27,2024

Different types of explosion-proof wrenches will have different effects

Explosion proof wrenches are an indispensable item in our daily lives. The indicators have all reached the advanced level of similar foreign products. The characteristics of different categories will naturally have different effects, so it is necessary to choose a suitable explosion-proof wrench in the actual operation process.

Nov 15,2019

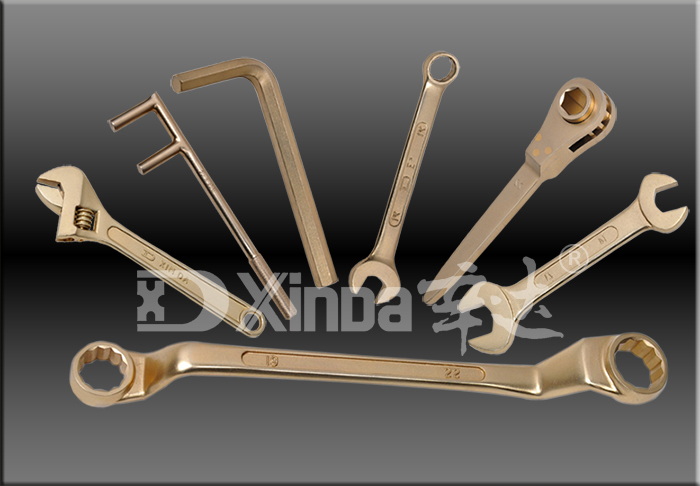

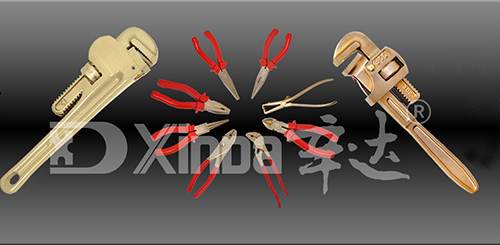

Why are explosion-proof wrenches made of copper?

Copper wrench is the most commonly used hand tool in the explosion proof tools,including non sparking striking box end wrench,open end wrench bent,single open end wrench,double end box end wrench,striking box end wrench bent,hex allen key,striking box end wrench convex,striking open end wrench,adjustable wrench,valve square driver,F wrench,combination wrench,double open end wrench,universal wrench,socket wrench,bung wrench,C wrench,hook wrench,ratchet wrench,T wrench and other hundreds of products with thousands of specifications.

Sep 30,2019

Classification and management of explosion-proof tools

There is abrasion or damage to the natural parts of the used tools, especially tools with blades. Trimming in non-hazardous areas.If the damage is severe and it is not suitable to repair it by yourself, it should be scrapped and cannot be operated.

Sep 30,2019

Mechanism of explosion-proof tools

The tools and equipment such as drills, picks, hammers, pliers, wrenches, and spreaders usually made of iron and steel materials during their fierce action or fall due to misses,will generate sparks which are hidden sources of ignition, so these tools cannot be used in explosion hazardous areas.

Sep 30,2019

What is explosion proof certification?

What is explosion proof certification? Explosion-proof certification is used to determine that the products meet the requirements of explosion-proof standards, type tests and routine tests for adaptation and to issue relevant certificates. Explosion proof certification products including non sparking hand tools,non sparking motors, appliances, lamps and lanterns, instruments and meters,communication equipment, transportation vehicles andmachinery and equipment (such as elevators and cranes).

Sep 30,2019

Applications of explosion-proof tools

Petroleum refining and petrochemical industry, coal mine, oil field, natural gas chemical industry, gunpowder industry, chemical fiber industry, paint industry, fertilizer industry, various pharmaceutical industries. Oil tankers and LPG vehicles, airplanes, warehouses operating flammable and explosive products, electrolytic workshops, telecommunication machine assembly workshops, places that require tools not rusty, wear-resistant and anti-magnetic.

Contact Us

E-mail :

info@xdtools.com

Phone/Wechat/WhatsApp:

+86-15830107628

Address:

Xinleitou Industry, Xinji City, Shijiazhuang City, Hebei Pro.,China.