Description

| 1991 Non sparking Testing Hammer | |||

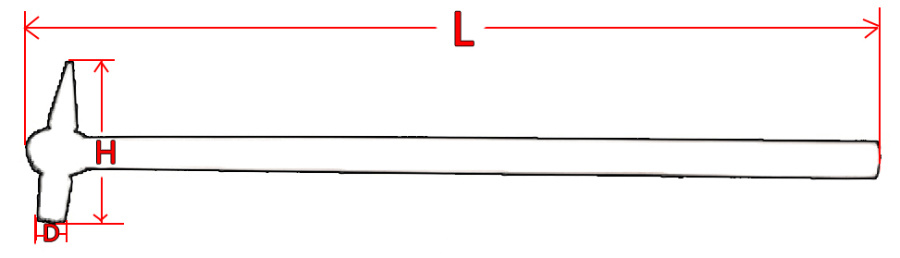

| SIZE | H(mm) | L (mm) | W(g) |

| 0.15kg | 105 | 400 | 265 |

| 0.25kg | 120 | 500 | 390 |

Technical

| Be-Cu | |

| Green lake, GBEX IC,for hydrogen with concentration 21.0+2.0%. | |

| Hardness | HRC35 |

| Tensile strength | δ b 105-120kgf/mm² |

| Al-Cu | |

| Bluish yellow, GBEX IIB, for ethylene with concentration 7.8+0.5% | |

| Hardness | HRC25 |

| Tensile strength | δ b 75-85kgf/mm² |

The non sparking testing hammer is mainly used to test the integrity and performance of explosion-proof tools. Its design is unique, with a pointed end that can effectively detect whether the equipment is damaged or loose. This not only ensures convenient operation but also ensures safety during the inspection process. The material is made of high-strength copper alloy, aluminum bronze, or beryllium bronze, with excellent explosion-proof performance. This product has wide applications in the field of explosion-proof and is suitable for flammable and explosive environments and situations. The explosion-proof testing hammer is an indispensable important tool in the field of industrial safety and is widely used in explosion-prone places such as oil, chemical, and mining industries.

Introducing the non sparking Testing Hammer Tip, an essential tool designed for precision and durability. Crafted with high-quality copper alloy materials, this explosion proof hammer tip ensures reliable performance in a variety of testing applications.

The main thing is to check if the connecting parts are loose. Just tap the screws and listen to the sound to see if they are loose. Also, check if the machine parts have failed. For example, tap the leaf spring. You can tell which part is loose or has cracks just by tapping. Apart from the sound, the feel of tapping the faulty component is also different.

1991 Testing hammer tip

Contact Us

Classification