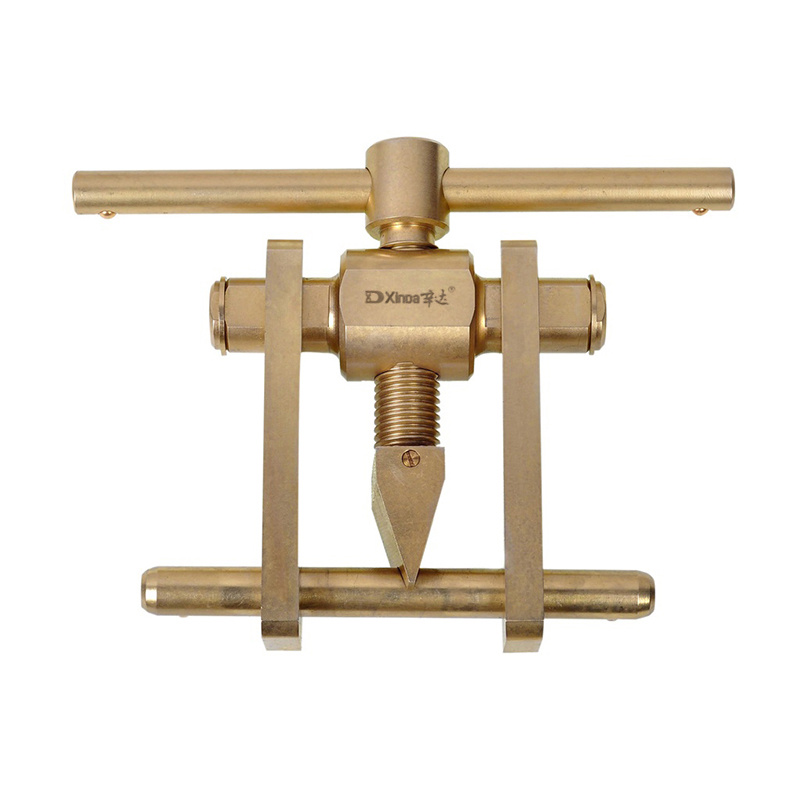

Description

| 2781 Non sparking Screw jack | |

| NO. | SIZE |

| 278101 | 6T |

| 278102 | 8T |

| 278103 | 10T |

| 278104 | 16T |

| 278105 | 20T |

In places prone to fire and explosion such as petrochemical plants, mines and power stations, traditional hydraulic jacks have safety hazards due to the possibility of generating static sparks. The non sparking screw jack, with its all-metal mechanical structure and explosion-proof material design, has become the core equipment for lifting heavy objects in such scenarios.

Safety design of non sparking screw jack

The material is selected as beryllium bronze or aluminum bronze alloy (with copper content ≥ 79%), and no sparks are generated during friction and collision, complying with the explosion-proof standard of GB/T 10686.

The static mechanical transmission structure completely avoids the risk of hydraulic oil leakage, and is suitable for Class II explosive gas environments (such as methane, ethylene, etc., high-risk media).

High-load precision control of non sparking screw jack

The trapezoidal thread screw is combined with self-locking nuts, and the single-stage lifting force can reach 10-20 tons, with a lifting accuracy of ±1mm.

Manual handle, with very little operating force, drives a large load, reducing manual fatigue.

Non sparking tools should have a proper maintenance phase after they are used in our daily work.it's critical to the life of the tools.lf the products can not be properly maintained,the tools will not service us long.First of all,we should keep the hand tools in the dry place,that can not damage our product parts.

Explosion proof tools keep our staff who worked in flammable,explosive and easy to corrosion place safe,so that our staff rest assured.

In our daily work,after 20 consecutinve strokes,we must treat the surface attachment of the copper hand tool and wipe it clean before using it,never using continuously.Prelonged friction can heat our products and damage our tools.

Copper hand tools

Company profile

Our non sparking products include Xinda brand beryllium bronze explosion-proof tools, aluminum bronze explosion- proof tools, and non-magnetic tools, which are divided into 10 categories and more than 180 series. They are made of high-strength copper alloy. The hardness and toughness index meet the standards. The explosion-proof performance complies with the national standard GB10686-2003, and has obtained the explosion-proof certificate issued by the National Coal Mine Explosion-proof Safety Product Quality Supervision and Testing Center. Products are widely used in petroleum, chemical industry, mining, coal, oxygen production, pharmaceuticals, smelting, leather and plastics industries. Sales cover all domestic provinces, regions and municipalities, and are exported to North America, Western Europe, the Middle East and Southeast Asia. We can also design and produce products with special specifications according to user needs.

The company has process equipment such as billet casting, forging, mechanical cutting, mold manufacturing, heat treatment and surface treatment, and has an independent explosion-proof tool R&D department and product testing department to provide guarantee for product quality and enterprise development.

Keywords

2781 Screw jack

Contact Us

Classification