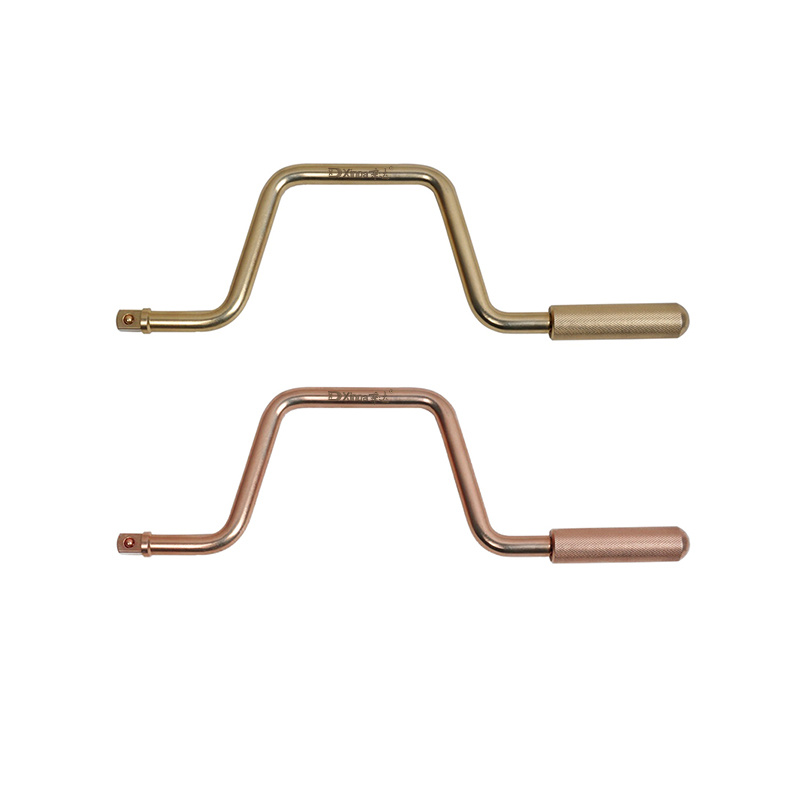

Description

| 1431 Sliding T bar | |

| NO. | SIZE |

| 143101 | 1/4”×100mm |

| 143102 | 3/8”×150mm |

| 143103 | 1/2”×250mm |

| 143104 | 3/4”×320mm |

| 143105 | 3/4”×430mm |

| 143106 | 1”×400mm |

| 143107 | 1”×500mm |

The non sparking sliding head handle is a tool designed for flammable and explosive environments. It is mainly used in places such as petroleum, chemical industry, and mining. Its characteristics are as follows:

1. Material and explosion-proof performance

It is made of aluminum bronze alloy or beryllium bronze alloy, which has explosion-proof and anti-magnetic properties to prevent sparks from rubbing between the tool and the workpiece and causing explosions. Among them, beryllium bronze material can also be used in a strong magnetic field environment.

2. Application scenarios

It is suitable for potentially explosive environments such as petroleum refining, chemical equipment maintenance, natural gas pipeline maintenance, and power plants.

3. Structural features

Adjustable sliding head design: The length of the force arm can be adjusted by moving the sliding head position to adapt to different operating requirements.

The handle length and diameter are diversified, with a common handle length range of 250-400mm and a handle diameter of 13-21mm, providing flexible operating options.

4. Models and parameters

Supports 1/2-inch, 3/4-inch and other specifications of socket head connection.

Technical

| Be-Cu | |

| Green lake, GBEX IC,for hydrogen with concentration 21.0+2.0%. | |

| Hardness | HRC35 |

| Tensile strength | δ b 105-120kgf/mm² |

| Al-Cu | |

| Bluish yellow, GBEX IIB, for ethylene with concentration 7.8+0.5% | |

| Hardness | HRC25 |

| Tensile strength | δ b 75-85kgf/mm² |

Keywords

1431 sliding T bar

Contact Us

Classification