Description

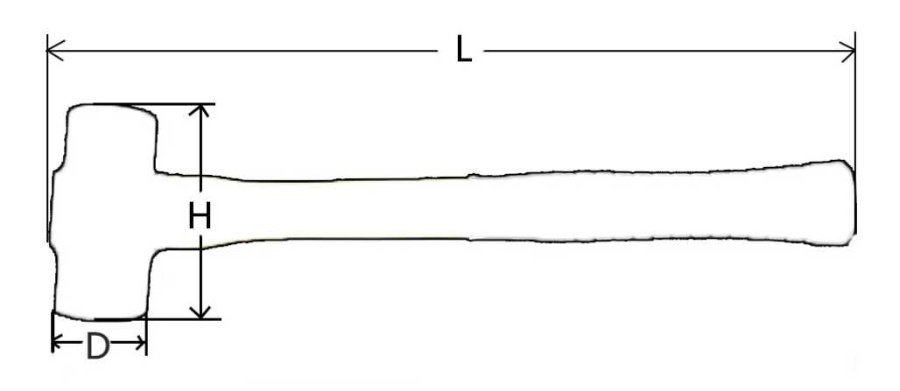

| 2001/2002 Non sparking Sledge Hammer | |||||

| SIZES | H(mm) |

L(mm) (wooden handle) |

L(mm) (fiberglass handle) |

W(g) (wooden handle) |

W(g) (fiberglass handle) |

| 0.9kg/2p | 95 | 370 | 370 | 1060 | 1145 |

| 1.4kg/3p | 105 | 400 | 390 | 1550 | 1695 |

| 1.8kg/4p | 121 | 400 | 400 | 1870 | 2055 |

| 2.7kg/6p | 138 | 800 | 750 | 2825 | 3010 |

| 3.6kg/8p | 145 | 800 | 750 | 3785 | 3810 |

| 4.5kg/10p | 168 | 900 | 900 | 4790 | 5065 |

| 5.4kg/12p | 175 | 900 | 900 | 5772 | 6025 |

| 6.3kg/14p | 182 | 900 | 900 | 6712 | 6995 |

| 7.2kg/16p | 190 | 900 | 900 | 7865 | 8012 |

| 8.1kg/18p | 202 | 900 | 900 | 8625 | 8975 |

I. Basic Overview of Non sparking sledge Hammer

The non sparking sledge hammer is a exposion proof tool specially designed for people who need to work in dangerous environments such as those prone to explosions and fires. Its main feature is to prevent explosions caused by sparks generated by the tool. The shape of the sledge hammer provides it with excellent mechanical properties and ease of operation.

II. Design Features

The non sparking hammer is designed uniquely, integrating engineering mechanics and modern technology. The hammer head is usually made of high-quality aluminum bronze or beryllium bronze alloy, featuring excellent corrosion resistance and explosion-proof properties. The handle part can be made of wood or plastic fiber materials to ensure a stable grip even in harsh environments. Moreover, its compact structure makes it convenient to carry and store.

III. Performance Advantages

1. High safety performance: The explosion-proof sledge hammer can provide high safety in explosive and flammable environments, effectively preventing safety accidents caused by sparks generated by the tool.

2. Strong practicality: Its octagonal shape design enables various striking methods during operation, meeting different operational requirements.

IV. Application Scenarios

Non sparking hammers are widely used in fields such as petroleum, chemical industry, coal mining, and fire protection where high safety is required. During equipment maintenance, pipeline repair, fire rescue and other operations, explosion-proof sledge hammers are indispensable tools.

Company profile

The company's products include Xinda brand beryllium bronze explosion-proof tools, aluminum bronze explosion- proof tools, and non-magnetic tools, which are divided into 10 categories and more than 180 series. They are made of high-strength copper alloy. The hardness and toughness index meet the standards. The explosion-proof performance complies with the national standard GB10686-2003, and has obtained the explosion-proof certificate issued by the National Coal Mine Explosion-proof Safety Product Quality Supervision and Testing Center. Products are widely used in petroleum, chemical industry, mining, coal, oxygen production, pharmaceuticals, smelting, leather and plastics industries. Sales cover all domestic provinces, regions and municipalities, and are exported to North America, Western Europe, the Middle East and Southeast Asia. We can also design and produce products with special specifications according to user needs.

2001 Sledge hammer wooden handle

Contact Us

Classification