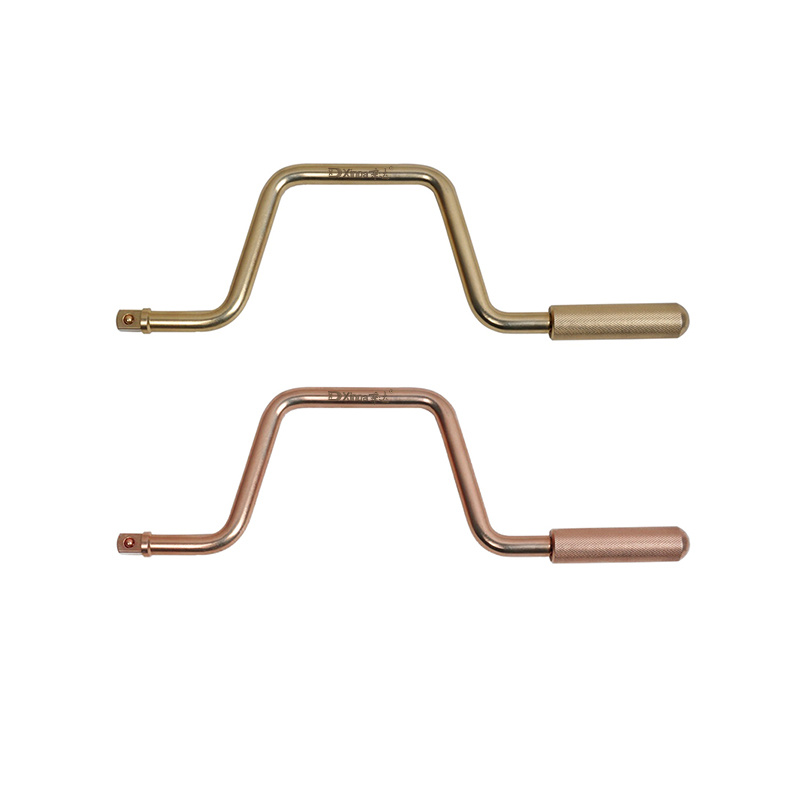

Description

| 1461 Hinged handle | |

| NO. | SIZE |

| 146101 | 1/4”×150mm |

| 146102 | 3/8”×200mm |

| 146103 | 1/2”×250mm |

| 146104 | 1/2”×320mm |

| 146105 | 1/2”×400mm |

| 146106 | 3/4”×300mm |

| 146107 | 1”×400mm |

The explosion-proof hinged handle is an important accessory in the non-sparking socket tools, used for operations in confined spaces. It is ingeniously designed and beautifully shaped, made of high-quality copper alloy materials, and has excellent durability and stability. The handle is of moderate length, in line with ergonomic design, providing a comfortable grip and allowing for flexible operation.

Applications

The non sparking hinged handle are widely used in petroleum,chemical industry,mining,gas,coal,oxygen-producing,pharmacy,smelting,powder,leather,airplane,marine engineering etc,suitable for warehouse that operate flammable and explosive products,electrolytic workshops,communication assembly workshops,and requires that the tools are not rusty,wear-resistant and anti-magnetic during the checking process.

Non- sparking spanners

Technical

| Be-Cu | |

| Green lake, GBEX IC,for hydrogen with concentration 21.0+2.0%. | |

| Hardness | HRC35 |

| Tensile strength | δ b 105-120kgf/mm² |

| Al-Cu | |

| Bluish yellow, GBEX IIB, for ethylene with concentration 7.8+0.5% | |

| Hardness | HRC25 |

| Tensile strength | δ b 75-85kgf/mm² |

Keywords

1461 Hinged handle

Contact Us

Classification