Description

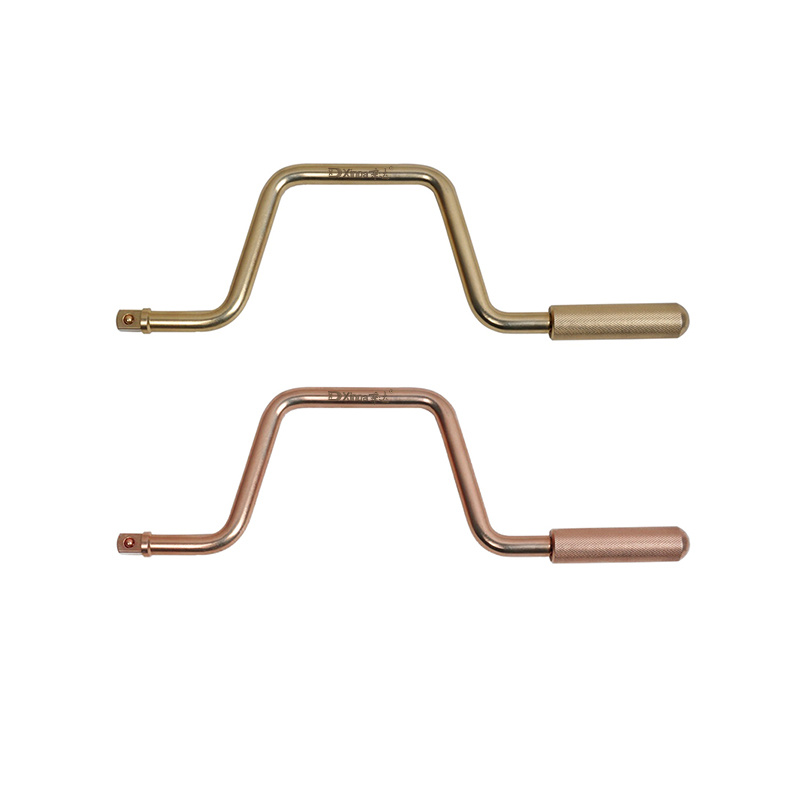

| 1421 Reversible Ratchet Wrench | |||

| NO. | SIZE | NO. | SIZE |

| 142101 | 1/4”×150mm | 142105 | 3/4”×430mm |

| 142102 | 3/8”×200mm | 142106 | 1”×500mm |

| 142103 | 1/2”×245mm | 142107 | 3/4”×160mm |

| 142104 | 3/4”×300mm | 142108 | 1”×180mm |

The non sparking reversing ratchet wrench is a professional tool designed for flammable and explosive environments. Its feature is that it uses advanced explosion-proof technology, which can provide a safe and stable operating experience in flammable and explosive places. The wrench is made of two materials, aluminum bronze and beryllium bronze, both of which are explosion-proof and spark-free materials. Its two-way ratchet design can provide good torque and steering force, ensuring that tasks can be easily completed even in a tense working environment. The wrench needs to be used with a matching sockets and is suitable for various specifications and models of sockets. In addition, it has a moderate length and is flexible and easy to operate. It is a practical tool that can adapt to a variety of scenarios. Whether it is in the petroleum, chemical or mining industries, the explosion-proof reversing ratchet wrench is an indispensable right-hand man.

Non sparking tools is also called safety tools or explosion proof tools.There are two types of materials.

1,Aluminum bronze,Al-Cu,aluminum,nickel,manganese,iron and other metals were added to the high purity electrolytic copper as matrix to form copper-based alloy.

2,Beryllium copper,Be-Cu,the copper base alloy was forming by adding some metals such as beryllium,nickel.

The thermal and electrical conductivity of these two materials are very good,beryllium bronze is non-magnetic and can be used in strong magnetic fields.

Explosion proof tools can be divided in two catagories by manufacturing process.

1.Cast,is a kind of traditional technique,it is an international technology for manufacturing explosion proof tools in 1980s.

Advantages of casting process: simple process,lower manufacturing cost.

Disadvantages: product density,hardness,tensile strength,low torque,more pores and trachoma lead to shorter service life.

2.Forging,is a kind of international manufacturing technology.Products can be made one-time forging by large press or punch press with heat-resistant forming die.

Advantages:greatly improved the performance in product density,hardness,tensile strenth,torque,basically eliminate porosity,trachoma.The machanical properties of products service life than traditional casting process 1 times.

Disavantages: product equipments,mold development,resulting higher cost.

Non- sparking spanners

Keywords

1421 Reversible ratchet wrench

Contact Us

Classification