Description

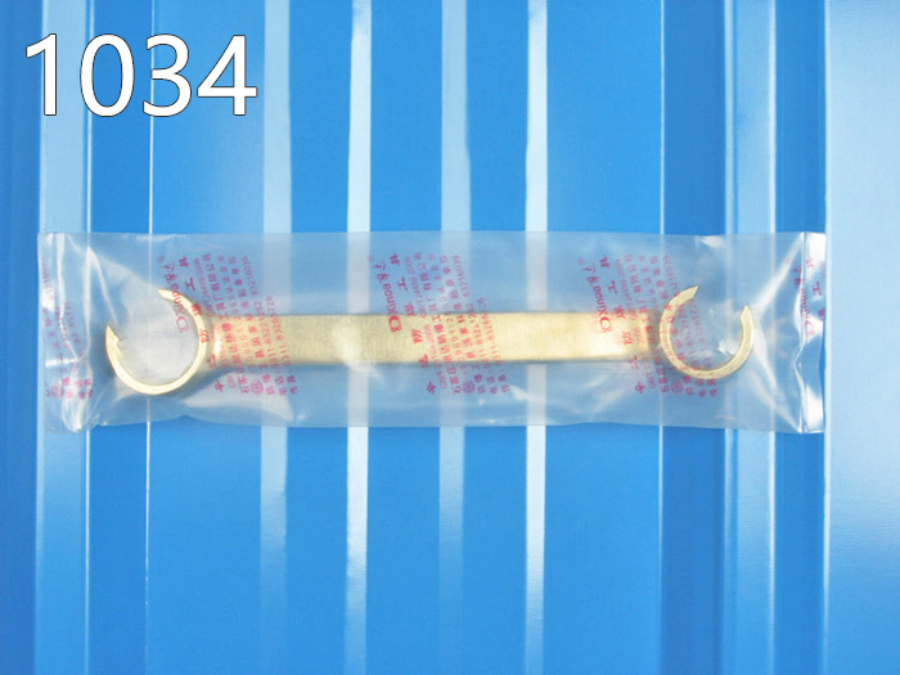

| 1034 Flare Nut Open Wrench | |

| NO. | SIZE |

| 103401 | 7×8mm |

| 103402 | 8×10mm |

| 103403 | 10×12mm |

| 103404 | 12×14mm |

| 103405 | 13×16mm |

| 103406 | 14×17mm |

| 103407 | 16×18mm |

| 103408 | 17×19mm |

| 103409 | 18×21mm |

| 103410 | 19×22mm |

| 103411 | 22×24mm |

| 103412 | 24×27mm |

| 103413 | 27×30mm |

| 103414 | 30×32mm |

Non sparking tools is also called safety tools or explosion proof tools.There are two types of materials.

1.Aluminum bronze.Al-Cu,aluminum,nickel,manganese,iron and other metals were added to the high purity electrolytic copper as matrix to form copper-based alloy.

2,Beryllium copper,Be-Cu,the copper base alloy was forming by adding some metals such as beryllium,nickel.

The thermal and electrical conductivity of these two materials are very good,berylium bronze is non-magnetic and can be used in strong magnetic fields.

Explosion proof tools can be divided in two catagories by manufacturing process

1.Cast, is a kind of traditional technique,it is an international technology for manufacturing explosion proof tools in 1980s.

Advantages of casting process: simple process,lower manufacturing cost.

Disadvantages: product density,hardness,tensile strength,low torque,more pores and trachoma lead to shorter service life.

2.Forging,is a kind of international manufacturing technology.Products can be made one-time forging by large press or punch press with heat-resistant forming die.

Advantages:greatly improved the performance in product density,hardness,tensilestrenth,torque,basically eliminate porosity,trachoma.The machanical properties of products serviceife than traditional casting process 1 times.

Disavantages: product equipments,mold development,resulting higher cost.

Technical

| Be-Cu | |

| Green lake, GBEX IC,for hydrogen with concentration 21.0+2.0%. | |

| Hardness | HRC35 |

| Tensile strength | δ b 105-120kgf/mm² |

| Al-Cu | |

| Bluish yellow, GBEX IIB, for ethylene with concentration 7.8+0.5% | |

| Hardness | HRC25 |

| Tensile strength | δ b 75-85kgf/mm² |

Introducing the non sparking Flare Nut Open Wrench, a must-have tool for any mechanic or DIY enthusiast. This wrench is designed to provide maximum grip and control when loosening or tightening flare nuts, making it an essential addition to your toolbox.

Crafted from high-quality materials, the non sparking Flare Nut Open Spanner boasts exceptional durability and strength, ensuring that it can withstand even the toughest of jobs. Its open-end design allows for easy access to tight spaces, while its precision-engineered jaw provides a secure grip on the nut, preventing slippage and damage to the threads.

One of the standout features of this wrench is its ergonomic handle, which is designed to fit comfortably in your hand and reduce strain during prolonged use. The handle is also textured to provide a secure grip, even when wearing gloves or working in wet conditions.

The Flare Nut Open Spanner is available in a range of sizes to suit different applications, so you can choose the one that best fits your needs. Whether you're working on plumbing projects, automotive repairs, or any other task that requires the use of flare nuts, this wrench is up to the challenge.

So why wait? Add the Flare Nut Open Wrench to your tool collection today and experience the difference that a high-quality tool can make. Order now and get ready to tackle any job with confidence!

1034 Flare Nut Open Wrench

Contact Us

Classification