Description

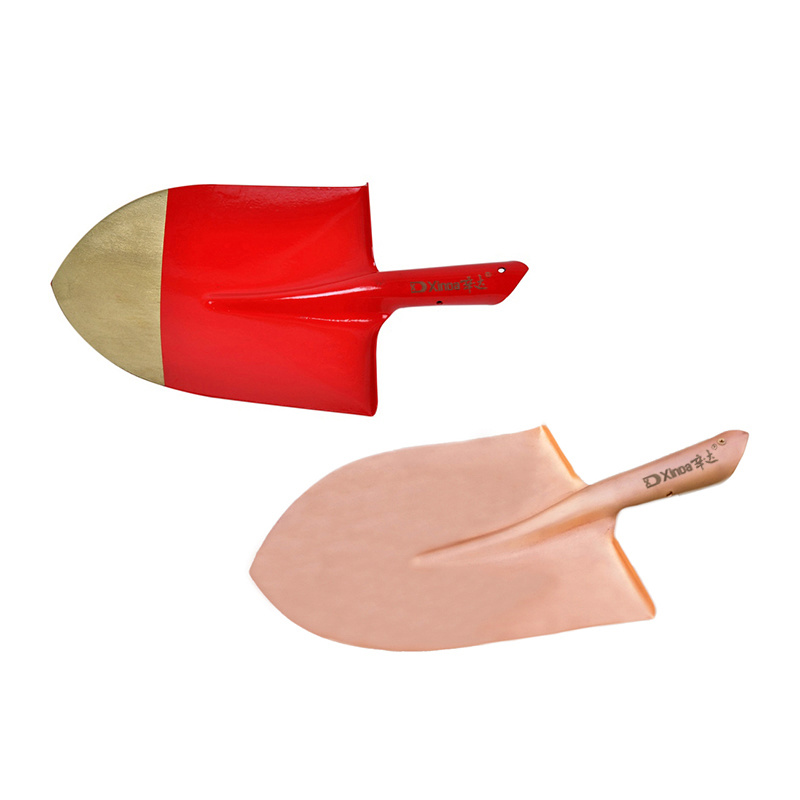

| 2191 Non sparking Shovel Scoop | |||

| NO. | SIZE | W(g) | |

| Be-Cu | Al-Cu | ||

| 219101 | 2# 510×275mm | 1705 | 1550 |

1. Basic concept of non sparking scoop shovel

The non sparking scoop shovel is a specially designed explosion proof tool, mainly used for operations such as excavation and shoveling. Its characteristics are that it uses special materials and processes to ensure that no sparks or ignitions occur in flammable and explosive environments, thereby effectively avoiding accidents.

2. Material and design of non sparking scoop shovel

The material of non sparking scooop shovel is usually high-strength, wear-resistant and corrosion-resistant copper alloy. Its design has also been carefully calculated to ensure that it can maintain explosion-proof performance while bearing high-intensity pressure. In addition, its surface has been specially treated to effectively prevent corrosion and oxidation.

3. Application fields of non sparking scoop shovel

Non sparking scoop shovel is widely used in industrial fields such as petroleum, chemical, mining, and pharmaceuticals. In these environments, due to the presence of flammable and explosive gases, the consequences of an accident are disastrous. Therefore, the use of explosion-proof scoop shovels can greatly reduce the probability of accidents and protect the lives of workers.

Non sparking tools is also called safety tools or explosion proof tools.There are two types of materials.

1,Aluminum bronze,Al-Cu,aluminum,nickel,manganese,iron and other metals were added to the high purity electrolytic copper as matrix to form copper-based alloy.

2,Beryllium copper,Be-Cu,the copper base alloy was forming by adding some metals such as beryllium,nickel.

The thermal and electrical conductivity of these two materials are very good,beryllium bronze is non-magnetic and can be used in strong magnetic fields.

Explosion proof tools can be divided in two catagories by manufacturing process.

1.Cast,is a kind of traditional technique,it is an international technology for manufacturing explosion proof tools in 1980s.

Advantages of casting process: simple process,lower manufacturing cost.

Disadvantages: product density,hardness,tensile strength,low torque,more pores and trachoma lead to shorter service life.

2.Forging,is a kind of international manufacturing technology.Products can be made one-time forging by large press or punch press with heat-resistant forming die.

Advantages:greatly improved the performance in product density,hardness,tensile strenth,torque,basically eliminate porosity,trachoma.The machanical properties of products service life than traditional casting process 1 times.

Disavantages: product equipments,mold development,resulting higher cost.

Keywords

2191 Shovel scoop

Contact Us

Classification