Description

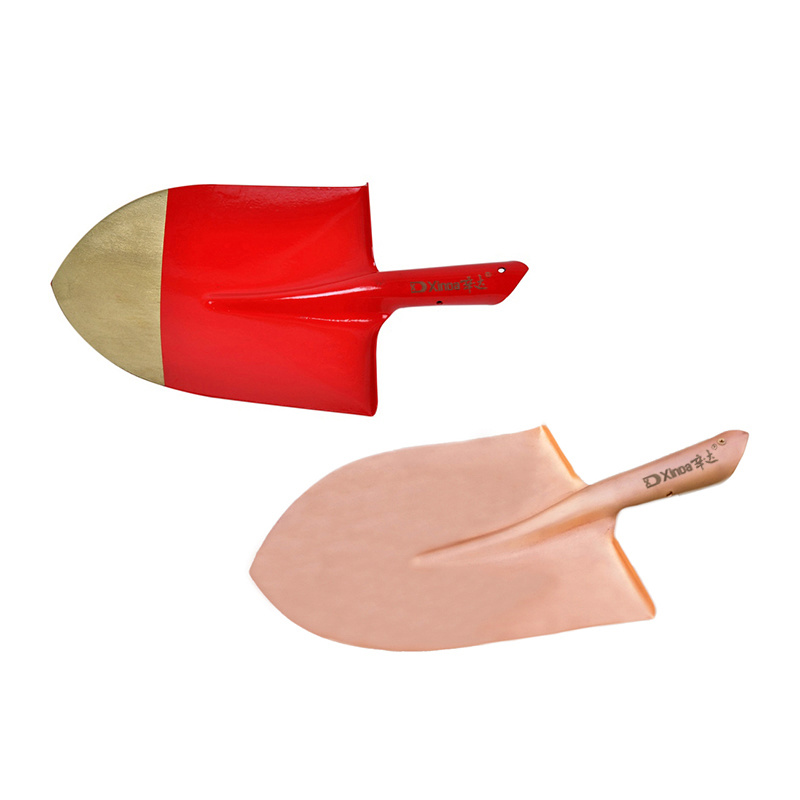

| 2151 Non sparking Square Shovel | |||

| NO. | SIZE | W(g) | |

| Be-Cu | Al-Cu | ||

| 215101 | 1# 420×245mm | 1166 | 1060 |

| 215102 | 3# 350×190mm | 334 | 720 |

1. Basic concept of non sparking square shovel

An non sparking square shovel is a specially designed explosion proof tool, mainly used for operations such as excavation and shoveling. Its characteristics are that it uses special materials and processes to ensure that no sparks or ignitions occur in flammable and explosive environments, thereby effectively avoiding accidents.

2. Material and design of non sparking square shovel

The material of non sparking square shovel is usually high-strength, wear-resistant and corrosion-resistant copper alloy. Its design has also been carefully calculated to ensure that it can maintain explosion-proof performance while bearing high-intensity pressure. In addition, its surface has been specially treated to effectively prevent corrosion and oxidation.

3. Application fields of non sparking square shovel

Non sparking square shovel is widely used in industrial fields such as petroleum, chemical, mining, and pharmaceuticals. In these environments, due to the presence of flammable and explosive gases, the consequences of an accident are disastrous. Therefore, the use of explosion-proof square shovels can greatly reduce the probability of accidents and protect the lives of workers.

The material is copper alloy,beryllium copper or aluminum bronze.Due to the good thermal conductivity of copper and high-quality stainless steel and the characteristics of almost no carbon, the heat generated in a short time is absorbed and conducted when the product is rubbed or impacted by an object.Another reason is that because copper and stainless steel are relatively soft, they have good concessions during friction and impact, and it is not easy to produce tiny metal particles.So we can hardly see the spark, the products achieve the explosion-proof effect.

Applications:Petroleum refining and petrochemical industry, coal mine, oil field, natural gas chemical industry, gunpowder industry, chemical fiber industry, paint industry, fertilizer industry, various pharmaceutical industries. Oil tankers and LPG vehicles, airplanes, warehouses operating flammable and explosive materials, electrolytic workshops, telecommunication machine assembly workshops, places that require products not to rust, wear-resistant and antimagnetic places.

Non sparking hand tools manufactuer.

Performance

The material of non sparking tools: Al-Br(QAl11-4-4), Be-Cu(QBe2)

Be-Cu: the color is green lake,hardness is not less than HRC35,tensile strength δ b 105-120kgf/mm2;standard code GBEX ⅡC,suitable for hydrogen with concentration 21.0±2.0%.Beryllium copper alloy with anti-magnetic performance.

Al-Cu: the color is bluish yellow,hardness is not less than HRC25,tensile strength δ b 75-85/mm2;standard code GBEX ⅡB,suitable for ethylene with concentration 7.8±0.5%,GBEX ⅡA (propane 6.5±0.5%),Ⅰ(methane 6.5±0.5%)。

Keywords

2151 Shovel square edge

Contact Us

Classification