Description

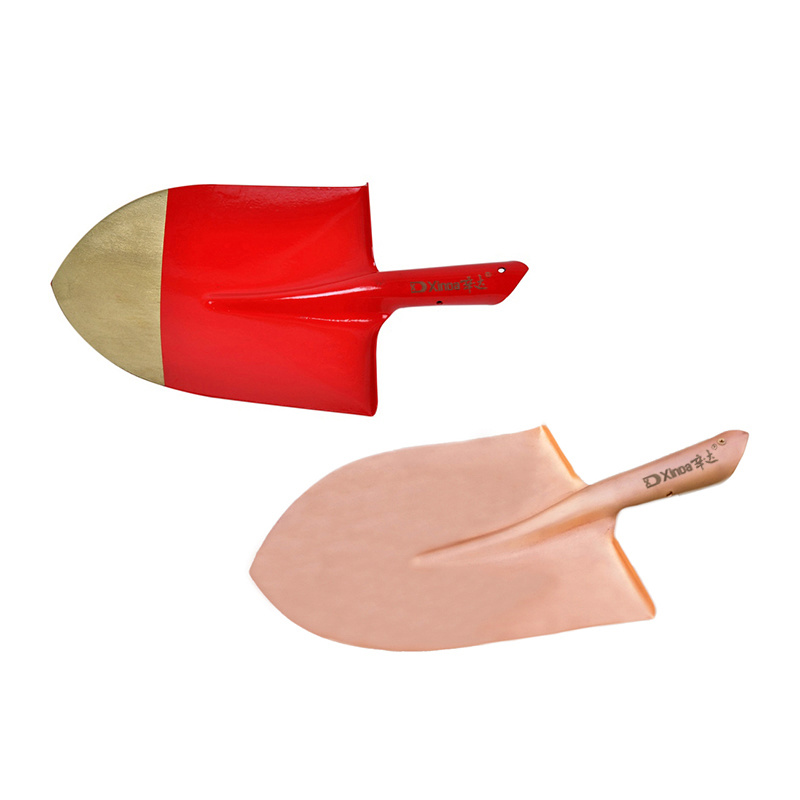

| 2181 Non sparking Round point Shovel wih D-handle | |||

| NO. | SIZE | W(g) | |

| Be-Cu | Al-Cu | ||

| 218101 | 2# 425×235mm | 1644 | 1495 |

1. Basic concept of non sparking round point shovel with D-handle

The non sparking round point shovel is a specially designed explosion proof tool, mainly used for operations such as excavation and shoveling. Its characteristics are that it uses special materials and processes to ensure that no sparks or ignitions occur in flammable and explosive environments, thereby effectively avoiding accidents.

2. Material and design of non sparking round shovel

The material of non sparking round shovel is usually high-strength, wear-resistant and corrosion-resistant copper alloy. Its design has also been carefully calculated to ensure that it can maintain explosion-proof performance while bearing high-intensity pressure. In addition, its surface has been specially treated to effectively prevent corrosion and oxidation.

3. Application fields of non sparking round shovel

Non sparking round shovel is widely used in industrial fields such as petroleum, chemical, mining, and pharmaceuticals. In these environments, due to the presence of flammable and explosive gases, the consequences of an accident are disastrous. Therefore, the use of explosion-proof shovels can greatly reduce the probability of accidents and protect the lives of workers.

Non sparking tools should have a proper maintenance phase after they are used in our daily work.it's critical to the life of the tools.lf the products can not be properly maintained,the tools will not service us long.First of all,we should keep the hand tools in the dry place,that can not damage our product parts.

Explosion proof tools keep our staff who worked in flammable,explosive and easy to corrosion place safe,so that our staff rest assured.

In our daily work,after 20 consecutinve strokes,we must treat the surface attachment of the copper hand tool and wipe it clean before using it,never using continuously.Prelonged friction can heat our products and damage our tools.

Copper hand tools

Performance

The material of non sparking tools: Al-Br(QAl11-4-4), Be-Cu(QBe2)

Be-Cu: the color is green lake,hardness is not less than HRC35,tensile strength δ b 105-120kgf/mm2;standard code GBEX ⅡC,suitable for hydrogen with concentration 21.0±2.0%.Beryllium copper alloy with anti-magnetic performance.

Al-Cu: the color is bluish yellow,hardness is not less than HRC25,tensile strength δ b 75-85/mm2;standard code GBEX ⅡB,suitable for ethylene with concentration 7.8±0.5%,GBEX ⅡA (propane 6.5±0.5%),Ⅰ(methane 6.5±0.5%)。

Non sparking tools of XIN DA are made of high strength copper alloy.This kind hand tools can effectively prevent burning and explosion accidents caused by friction and collision between tools and tools in the flammable and explosive workplace.The explosion-proof performance received the certificates according to the national standard GB10686-2003, with the function of high intensity and good toughness.

Keywords

2181 Shovel round point with D-handle

Contact Us

Classification