Description

| 2242 Non sparking Scraper rust | |||

| NO. | SIZE | NO. | SIZE |

| 224201 | 75×600mm | 224203 | 75×1000mm |

| 224202 | 75×800mm | 224204 | 75×1200mm |

Non sparking rust scraper is a copper alloy explosion proof hand tool designed for flammable and explosive environments.The scraper is for rust removal.

1. Core features of the non sparking scraper

Explosion-proof principle

Made of beryllium bronze (Be-Cu) or aluminum bronze (Al-Cu), the high thermal conductivity and low friction characteristics of the material prevent sparks during operation and have corrosion resistance.

Beryllium bronze products have anti-magnetic properties and are suitable for strong magnetic fields or chemical corrosion environments. Beryllium bronze has a higher explosion-proof grade

Applicable places

Repair and maintenance of explosive and high-risk areas such as petrochemical plants, natural gas filling stations, coal mines, and flammable gas transport vehicle maintenance stations.

2. Specifications of the non sparking scraper are shown in the table above.

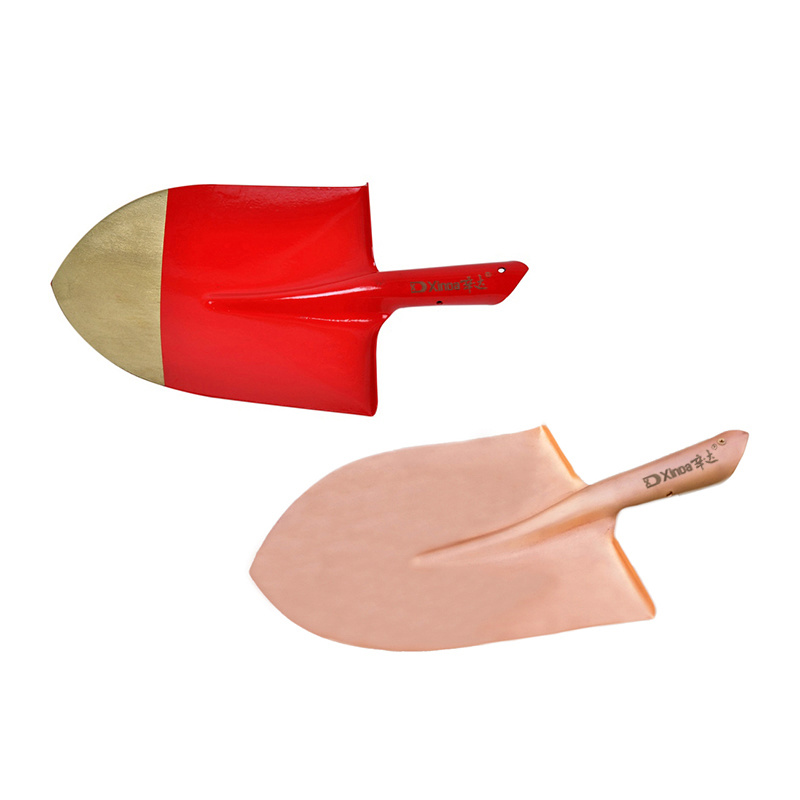

3. Structural design of the non sparking scraper

Arched shovel: The shovel head is arc-shaped, which is convenient for cleaning rust on curved surfaces.

Double-head scraper: Different blade shapes (flat/pointed) at both ends to meet a variety of rust removal needs.

Handle-mounted type: The wooden handle or fiberglass handle can be replaced to enhance operational flexibility.

️ IV. Use and Maintenance of the non sparking scraper

Operation Taboo: Overload scraping or hammering (non-special striking tools) is prohibited.

Regular inspection: Severely worn scraper blades need to be replaced in time to avoid brute force operation.

Non-sparking scraper can be also used in marine enginerring,the material is aluminum bronze or beryllium copper.

Be-Cu:

Suitable for hydrogen with concentration below 21%,standard code GBEX ⅡC

Hardness is not less than HRC35,Tensile strength δ b 105-120kgf/mm

Beryllium copper alloy with anti-magnetic performance.

Al-Cu:

Suitable for ethylene with concentration below 7.8%,standard code GBEX ⅡB

Hardness is not less than HRC25,Tensile strength δ b 75-85kgf/mm2

Non sparking spanner,Explosion proof Tools

Company profile

The company's products include Xinda brand beryllium bronze explosion-proof tools, aluminum bronze explosion- proof tools, and non-magnetic tools, which are divided into 10 categories and more than 180 series. They are made of high-strength copper alloy. The hardness and toughness index meet the standards. The explosion-proof performance complies with the national standard GB10686-2003, and has obtained the explosion-proof certificate issued by the National Coal Mine Explosion-proof Safety Product Quality Supervision and Testing Center. Products are widely used in petroleum, chemical industry, mining, coal, oxygen production, pharmaceuticals, smelting, leather and plastics industries. Sales cover all domestic provinces, regions and municipalities, and are exported to North America, Western Europe, the Middle East and Southeast Asia. We can also design and produce products with special specifications according to user needs.

The company has process equipment such as billet casting, forging, mechanical cutting, mold manufacturing, heat treatment and surface treatment, and has an independent explosion-proof tool R&D department and product testing department to provide guarantee for product quality and enterprise development.

2242 Scraper rust

Contact Us

Classification